Tech-Driven Solutions

Maximizing thermal energy efficiency plays the highest importance nowadays, particularly to the thermal power plant and building management industries. Recent breakthroughs in phase-change materials are worth a great deal for this purpose. This can reduce cooling energy usage by as much as 30% in data centers.

Knowing about thermal management is important. It helps to make systems like heat engines work better. New ways of using thermal energy and conserving energy are also being developed. In India, efforts are being made in making the thermal power plants more efficient. Investments have been made in new technology to reduce emissions and boost output.

This blog looks at the latest ways to improve thermal efficiency. We explore their uses and how they help save energy and protect the environment.

Key Takeaways

- Boosting thermal energy efficiency is key for success and sustainability.

- To enhance performance, new technologies like PCMs, geothermal systems, and smart management tools are important.

- Effective conservation strategies can save a lot of money and reduce any harm to the environment.

- AITD training programs train professionals in the effective use of those innovations.

Understanding Thermal Efficiency: What It Is and What It Means

Thermal efficiency is the number of useful works divided by the heat input. This is expressed in percentage terms. It indicates how effective a thermal device is at converting heat into work or other useful output. The expression for thermal energy efficiency η is given as

η=WQin×100η=Qin W ×100

Here, ww denotes work, and qin,qin represents heat input. Measurement in this regard serves for testing such devices such as internal combustion engines, boilers, and turbines.

Important Definitions

- Thermal Efficiency Definition: It is the ratio of how much heat energy is converted to work.

- Thermal Efficiency Equation: η=WQin×100η=Qin W ×100.

- Thermal Power Plant Efficiency: Generally, ranges between 30% to 60%, depending upon technology and fuel.

- Thermal Efficiency of Engine: This number varies widely; gasoline engines average about 25%.

DO YOU KNOW? The global average thermal power plant efficiency is about 33%, which, with new technologies, leaves much scope for improvement.

Improving Thermal Power Plant Efficiency Worldwide New Innovations.

1. Improved Heat Exchangers

Advanced materials improve the heat transfer rates of modern exchangers and minimize energy loss. These innovations allow industries to recover waste heat from a process and improve general efficiency in thermal terms.

2. Combined Cycle Power Plants

There are even combined cycle power plants, whereby the efficiency of gas and steam turbines can reach over 60%. This becomes possible due to these using the waste heat in gas turbines to supplement that electricity, produced through creation of steam.

3. Waste Heat Recovery Systems

These systems capture the surplus of industrial process heat generated and utilize them to either heat or generate electricity. In the process, they are likely to increase the thermal efficiency of heat engine as well as conserve fuel consumption.

4. Intelligent Thermostats

Smart thermostats have the ability to transform energy management through a capable learning behavior for users to optimize heating and cooling schedules. The possibilities of this technology are very strong for residential and industrial applications for thermal energy conversation.

DO YOU KNOW? PCM-based cooling systems can save energy use by around 25%.

5. Phase Change Materials (PCMs)

PCMs retain thermal energy in the form of phase transitions. Consequently, PCMs constitute an environment-friendly temperature swing management system applicable to buildings and industrial processes. Including PCMs in thermal systems optimizes energy management performance.

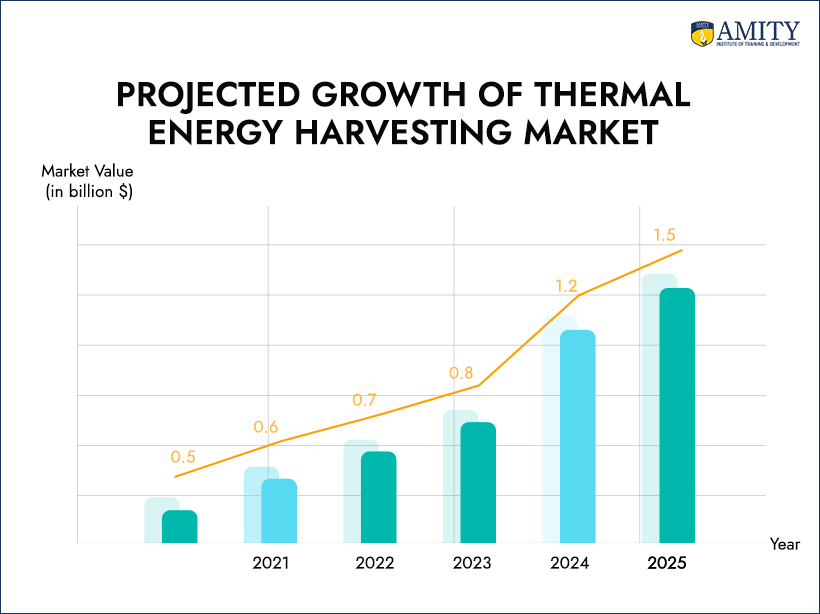

DO YOU KNOW? Thermal Energy Harvester Market Has a CAGR of 12%, with an Expected $1.5 Billion in 2025.

Strategies for Effective Thermal Energy Conservation in Industry

Thermal energy conservation is the ability to reduce energy usage while maintaining comfort. Some good strategies are:

- Use better insulation that prevents heat from leaking out.

- Smart thermostats that self-discover your choices and change the schedule.

- Adding power from renewable sources to the traditional ones in order to increase efficiency.

Why Is Thermal Power Plant Efficiency in India Critical for National Energy Goals?

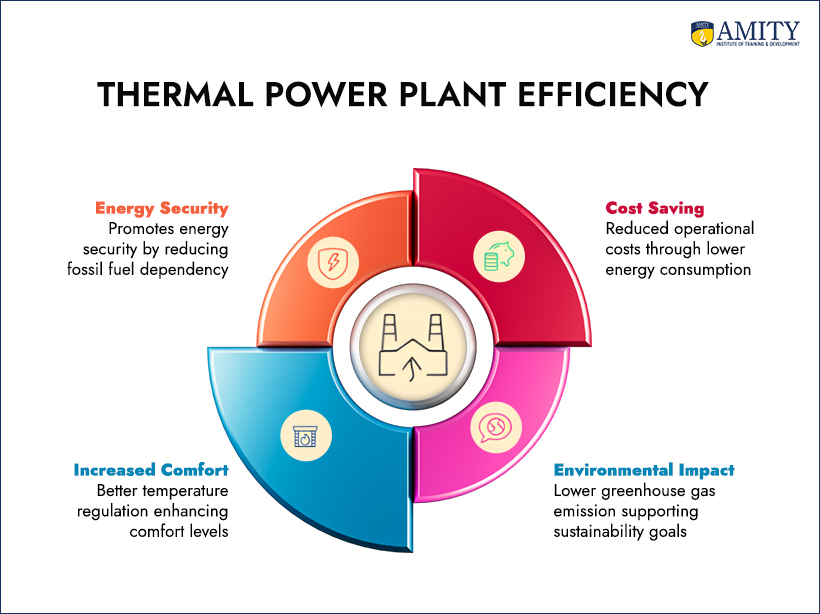

Improving thermal energy efficiency will have plenty of benefits:

- It saves costs: Better efficiency leads to taking in less energy, thus bringing in savings in terms of bringing down the costs.

- Environmental impact: This also means reduced pollution, which helps the planet.

- Comfort: It maintains the appropriate temperatures, ensuring places become comfortable.

- Security: It reduces our dependency on fossil fuel, which makes energy more secure.

DO YOU KNOW? AITD has assisted more than 500 companies in saving 20% of their energy.

The Role of Thermal Energy Conservation in Sustainable Business Practices

Thermal energy harvesting in productive manners is possible only through the installment of technologies that would capture waste heat into productive activities. Among these, one can implement the incorporation of heat recovery systems to all existing processes while researching new materials such as PCMs.

In “Innovative Strategies for Thermal Energy Optimization and Renewable Energy Integration in Net-Zero-Energy Buildings: A Comprehensive Review,”a research study by Ascione, De Masi, et al. carried out in previous year, methods were discussed regarding the efficiency of buildings. They discovered that PCS and geothermal systems could save more than 60% of energy. They also showed that smart systems, and predictive control could increase efficiency in many different types of weather.

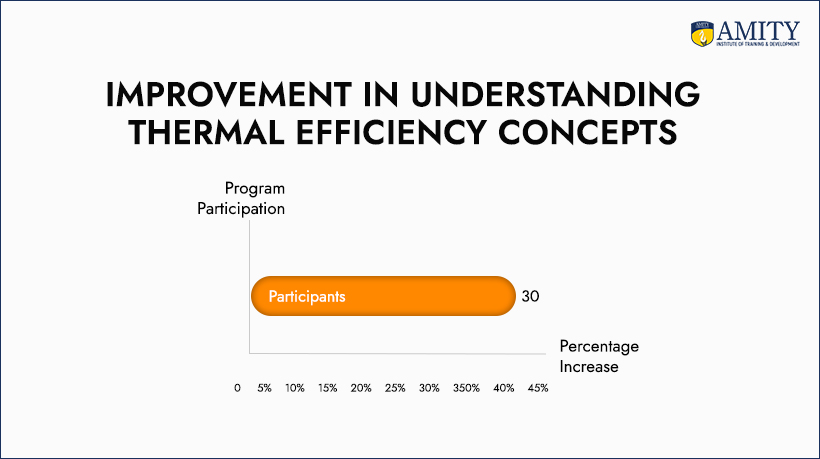

DO YOU KNOW? AITD programme beneficiaries get a 30% better understatement of thermal management.

What Impact Does Training Have on the Thermal Efficiency of Heat Engines?

Corporate training is indispensable for engineers and technicians. This allows them to learn the latest about thermal efficiency of engines. New-tech programs on maintenance and sustainability boost the performance levels of the engine and decrease its emissions.

How Can AITD Help Maximize Thermal Energy Efficiency?

Thermal energy efficiency forms the core of a future that is sustainable. The performance of the systems, such as in thermal power plants, reduces the costs and causes less damage to the environment. At AITD, we instruct the newest in thermal energy harvesting, the thermal efficiency of engines, and thermal energy conservation.

DO YOU KNOW? Companies adopting AITD measures experience a reduction of 15% in energy-related expenditures.

How Can AITD Training Assist Companies to Improve the Thermal Efficiency of Heat Engines?

AITD teaches:

- Thermal energy harvesting methods.

- Ways to boost thermal power plant efficiency, especially in India.

- Strategies for thermal energy conservation and better thermal efficiency of heat engines.

AITD’s Commitment to Training and Development

AITD’s programs include thermal systems and their efficiency. The learner ends up with an understanding of the thermal efficiency of heat engines as well as its application to real world conditions. This raises innovation in thermal management across industries.

The Future of Thermal Efficiency with AITD

A future critical outlook for AITD lies with its role in sustainable energy. It trains heat transfer efficiency, which enables companies to innovate. This can boost performance and also realize sustainability goals for the world.